Gamma Irradiation is the process of exposing various products to ionizing gamma rays (similar to UV and X-rays) in a highly controlled manner for a specific goal, such as elimination of virus, bacteria, pathogens, insects and other undesirable organisms etc. The gamma rays, which are a form of electromagnetic radiation of very short-wave lengths, act as a source of ionising energy that destroys bacteria and pests.

The isotope Cobalt-60 is the most common source of gamma rays for irradiation processing. The Cobalt-60 is manufactured specifically for the irradiation process and is housed in specially designed doubly encapsulated Stainless Steel Pencils housed in a specially designed system operating to strict standards and regulations.

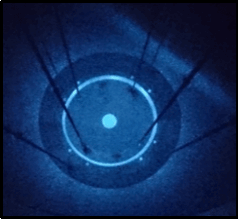

Cobalt 60 can be stored safely in a pool of water, while the chamber above the pool is surrounded by a thick concrete barrier that prevents gamma rays from escaping when the gamma source is elevated into the irradiation chamber. Product intended for medical sterilization is packaged, palletized, and transported into the irradiation chamber using a conveyor.

Gamma irradiation is known as a ‘Cold Process’ as the temperature of the processed product does not increase significantly. It is also a chemical free process that is not reliant on humidity, temperature or pressure.